Line Pipe Extrusion PE dị elu nke ọma

Nkọwa

A na-eji igwe ọkpọkọ Hdpe eme ihe maka imepụta ọkpọkọ ogbugba mmiri n'ubi, ọkpọkọ drainage, ọkpọkọ gas, ọkpọkọ na-enye mmiri, ọkpọkọ eriri USB wdg.

PE ọkpọkọ extrusion ahịrị nwere ọkpọkọ extruder, ọkpọkọ anwụ, nkeji nhazi, tank jụrụ oyi, ebugharị, cutter, stacker / coiler na akụkụ niile. Igwe na-emepụta ọkpọkọ Hdpe na-emepụta ọkpọkọ nwere dayameta site na 20 ruo 1600mm.

The ọkpọkọ nwere ụfọdụ magburu onwe atụmatụ dị ka kpo oku eguzogide, ịka nká na-eguzogide, elu n'ibu ike, gburugburu ebe obibi mgbawa cracks eguzogide, ezi creep eguzogide, wdg Hdpe pipe extrusion igwe e mere na elu arụmọrụ extruder na onwem na reducer nke bụ elu na-agba na obere mkpọtụ, gravimetric dosing unit na ultrasonic ọkpụrụkpụ egosi nwere ike kpọkọta dị ka ndị ahịa chọrọ ịrịgo nke ọkpọkọ.

Tụgharịa isi ihe ngwọta nwere ike inye, dị ka laser na-ebi akwụkwọ crusher, shredder, mmiri chiller, ikuku compressor wdg iji nweta elu-ọkwa na akpaka tube mmepụta.

Usoro Usoro

Raw material+ Master Batches → Mixing → Vacuum Feeder → Plastic Hopper Drier → Single screw extruder → Co-extruder for color string & Multi Layers → Mold and calibrator→ Vacuum calibration Tank → Spray Cooling Water Tank → Igwe na-ewepụ → igwe na-egbutu → Stacker (igwe ikuku)

Atụmatụ na Uru

1.Hdpe ọkpọkọ igwe na-emepụta site na anyị dabere na nkà na ụzụ Europe dị elu na ahụmahụ R & D nke igwe plastik ruo ọtụtụ afọ, nhazi dị elu, nhazi ezi uche, ntụkwasị obi dị elu, akpaaka dị elu.

2. Hdpe ọkpọkọ extruder na pụrụ iche gbọmgbọm nri Ọdịdị nwere ike n'ụzọ dị ukwuu melite extrusion ikike.

3. njikwa oke ọkụ, ezigbo plasticization, arụ ọrụ kwụsiri ike.

4. Hdpe ọkpọkọ igwe na-anabata usoro njikwa PLC, na-achọpụta mmekọrịta na akpaaka.

5. Ngwa mmadụ-kọmputa dị mfe iji rụọ ọrụ, adaba na ntụkwasị obi.

6. Spiral na lattice nkata ụdị anwụ anwụ maka nhọrọ.

7. Ịgbanwe akụkụ ụfọdụ nke ahịrị nwekwara ike ịghọta abụọ-layer na multi-layer co-extrusion.

8. Ịgbanwe akụkụ ụfọdụ nke akara ahụ nwekwara ike ịmepụta PP, PPR ọkpọkọ.

Nkọwa

Otu ịghasa Extruder

Dabere na 33: 1 L / D ruru maka ịghasa imewe, anyị emepụtala 38: 1 L / D ruru. E jiri ya tụnyere 33: 1 ratio, 38: 1 ratio nwere uru nke 100% plasticization, na-abawanye mmepụta ikike site 30%, belata ike oriri ruo 30% na iru fọrọ nke nta linear extrusion arụmọrụ.

Simens Touch Screen na PLC

Tinye mmemme nke ụlọ ọrụ anyị mepụtara, nwee Bekee ma ọ bụ asụsụ ndị ọzọ ka ọ bụrụ ntinye n'ime usoro ahụ.

Ihe owuwu gburugburu Barrel

Nri akụkụ gbọmgbọm na-eji usoro okirikiri, iji hụ na nri akụrụngwa kwụsiri ike ma na-abawanye ikike inye nri.

Pụrụ iche imewe nke ịghasa

Emebere ịghasa na ihe owuwu pụrụ iche, iji hụ na ọ dị mma plasticization na ịgwakọta. Ihe agbazeghị agbaze enweghị ike ịgafe akụkụ nke ịghasa.

Igwe ọkụ seramiiki jụrụ ikuku

Igwe na-ekpo ọkụ seramiiki na-eme ka ọ dị ogologo ndụ ọrụ. Nhazi a bụ ịbawanye mpaghara nke ikpo ọkụ na-akpọtụrụ ikuku. Ka inwe mmetụta dị jụụ ikuku ka mma.

Igbe igbe dị mma

A ga-ahụta izi ezi Gear 5-6 ọkwa yana obere mkpọtụ n'okpuru 75dB. Kọmpat Ọdịdị ma na elu torque.

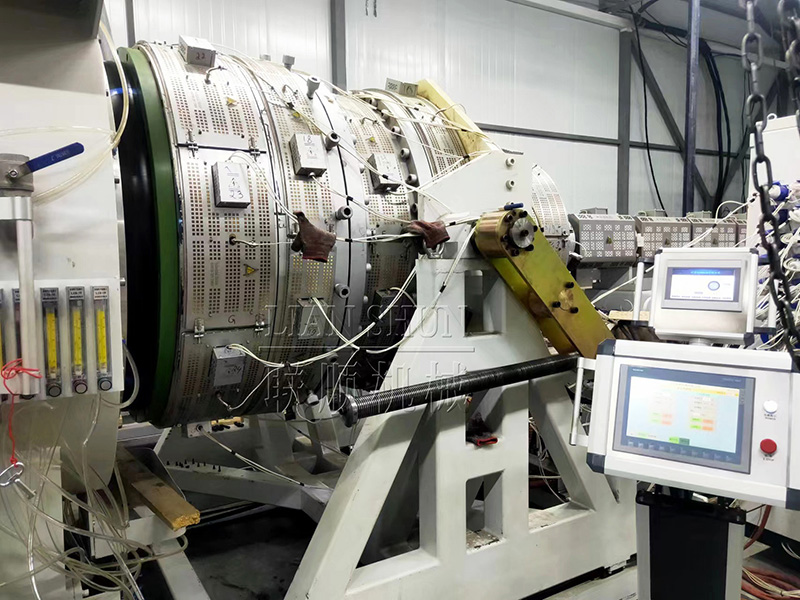

Extrusion anwụ Isi

Extrusion anwụ isi tinye gburugburu Ọdịdị, onye ọ bụla ihe eruba ọwa na-enịm evenly. Ọwa ọ bụla na-esote ọgwụgwọ okpomọkụ na polishing mirror iji hụ na ihe na-aga nke ọma. Ọdịdị isi anwụ bụ kọmpat ma na-enyekwa nrụgide kwụsiri ike, mgbe niile site na 19 ruo 20Mpa. N'okpuru nrụgide a, àgwà ọkpọkọ dị mma na mmetụta dị ntakịrị na ikike mmepụta. Nwere ike ịmepụta otu oyi akwa ma ọ bụ ọkpọkọ multi-layer.

Ngwaọrụ na-ebugharị nke isi anwụ anwụ

Maka nnukwu isi anwụ anwụ, ngwaọrụ na-akpụ akpụ nwere ike ịkwaga n'isi na azụ, na-edozikwa ịdị elu nke isi anwụ. Ọrụ dị ngwa ma dị mfe.

Ngwaọrụ Rotary anwụ Isi

Maka nnukwu isi anwụ anwụ nwere ngwaọrụ rotary, isi anwụ nwere ike ịtụgharị site na ogo 90. Mgbe ị na-agbanwe ohia, mandrel, isi anwụ ga-atụgharị ogo 90. Nwere ike iji kreenu bulie ma gbanwee ohia na mandrel. Ụzọ a dị nnọọ mma.

Ngwaọrụ na-ekpochapụ ọkụ

A na-agbakwunye ngwaọrụ a na isi anwụ iji mepụta ọkpọkọ buru ibu ma buru ibu. Iji gwụ okpomọkụ n'ime ọkpọkọ na ọkpọkọ jụrụ n'ime mgbidi. Enwere ike iji ihe na-ekpo ọkụ na-ekpo ọkụ mee ihe iji kpoo ihe ọkụkụ.

Ngwaọrụ jụrụ oyi maka Core

Mgbe a na-emepụta ọkpọkọ nwere nnukwu dayameta na ọkpụrụkpụ mgbidi, anyị ga-eji mmiri jụrụ oyi ma ọ bụ mmanụ na-ekpo ọkụ na-ekpo ọkụ na-eme ka isi ihe na-eme ka ọ dị jụụ iji zere ikpo ọkụ ma hụ na ihe onwunwe dị mma.

Mmanụ na-ekpo ọkụ ọkụ

A na-eji tankị Vacuum Calibration na-akpụzi ma mee ka ọkpọkọ dị jụụ, ka o wee ruo nha ọkpọkọ ọkọlọtọ. Anyị na-eji nhazi ụlọ okpukpu abụọ. Ụlọ nke mbụ dị n'ogologo dị mkpụmkpụ, iji hụ na ọ na-arụ ọrụ oyi na agụụ. Dị ka calibrator na-etinye n'ihu nke mbụ ụlọ na ọkpọkọ udi na-etolite tumadi site calibrator, a imewe nwere ike hụ na ngwa ngwa na mma akpụ na jụrụ ọkpọkọ.

Ike jụrụ oyi maka Calibrator

Site na usoro dị jụụ pụrụ iche maka calibrator, nke nwere ike inwe mmetụta dị mma maka ọkpọkọ ma hụ na oke ọsọ. Ọzọkwa na ezigbo mma ịgba nozulu na-enwe mma jụrụ mmetụta na adịghị mfe egbochi site adịghị.

Nkwado ka mma maka ọkpọkọ

Maka ọkpọkọ buru ibu, nha ọ bụla nwere efere nkwado nke semicircular nke ya. Ihe owuwu a nwere ike idobe okirikiri ọkpọkọ nke ọma.

Onye na-agbachi nkịtị

Anyị na-edobe silencer na vacuum adjust valve iji belata mkpọtụ mgbe ikuku batara n'ime tankị agụụ.

Valve enyemaka nrụgide

Iji chebe tankị agụụ. Mgbe ogo oghere ruru oke oke, valvụ ahụ ga-emeghe na akpaghị aka iji belata ogo agụụ ka ịzenarị agbaji nke tank. Enwere ike imezi mmachi oghere oghere.

Pipeline Ugboro abụọ

Loop nke ọ bụla nwere usoro nzacha mmiri, iji nye mmiri jụrụ oyi n'ime tank. Ugboro abụọ na-ahụ maka inye mmiri jụrụ oyi n'ime tank.

Mmiri, gas Separator

Iji kewaa mmiri mmiri gas. Ike gwụrụ gas site na elu. Mmiri na-asọba n'ime ala.

Njikwa mmiri na-akpaghị aka zuru ezu

Na n'ibu njikwa okpomọkụ ka nwere ziri ezi na kwụsiri ike akara nke mmiri okpomọkụ.

A na-achịkwa usoro ntinye mmiri na ntinye mmiri zuru oke na-akpaghị aka, kwụsiri ike na ntụkwasị obi.

Ngwaọrụ na-ekpofu ebe etiti

A na-ejikọta mmiri niile na-esi na tankị na-ekpo ọkụ ma jikọta ya na otu ọkpọkọ igwe anaghị agba nchara. Naanị jikọọ pipeline agbakwunyere na drainage n'èzí, iji mee ka ọrụ dị mfe na ngwa ngwa.

fesa tank mmiri jụrụ oyi

A na-eji tankị jụrụ oyi mee ka ọkpọkọ dị jụụ.

Ngwaọrụ na-amachi ọkpọkọ

Ngwaọrụ a nwere ike ịhazigharị ọkpọkọ ọkpọkọ mgbe ọkpọkọ na-apụta na tankị agụụ.

Ihe nzacha mmiri mmiri

Na nzacha n'ime tank mmiri, iji zere nnukwu adịghị ọcha mgbe mmiri dị n'èzí batara.

Ọdịmma fesa nozzle

Ọdịmma ịgba nozzles nwere mmetụta dị jụụ ka mma yana adịghị mfe egbochi ya site na adịghị ọcha.

Ngwaọrụ Na-edozi Nkwado Ọkụ

Nkwado na ọrụ nhazi iji kwado ọkpọkọ nwere dayameta dị iche iche.

Ngwaọrụ Nkwado Pipe

A na-ejikarị eme ihe mgbe ị na-emepụta ọkpọkọ na nnukwu dayameta na mgbidi mgbidi. Ngwaọrụ a ga-enye nkwado ọzọ na ọkpọkọ dị arọ.

Bupụ igwe

Igwe ebugharị na-enye ike traction zuru oke iji dọpụta ọkpọkọ kwụsie ike. Dị ka dị iche iche ọkpọkọ nha na ọkpụrụkpụ, anyị ụlọ ọrụ ga-ahazi traction ọsọ, ọnụ ọgụgụ nke claws, irè traction ogologo. Iji hụ na ngwa ngwa extrusion ọkpọkọ na-akpụ akpụ, zerekwa nrụrụ ọkpọkọ n'oge traction.

Moto traction dị iche

Ụkwụ ọ bụla nwere moto traction nke ya, ọ bụrụ na otu moto traction kwụsịrị ịrụ ọrụ, moto ndị ọzọ ka nwere ike ịrụ ọrụ. Nwere ike ịhọrọ moto servo ka ọ nwee ike traction buru ibu, ọsọ traction kwụsiri ike yana oke ọsọ traction sara mbara.

Ngwa ndozi Claw

A na-ejikọta eriri niile na ibe ya, mgbe ị na-edozi ọnọdụ nke claws iji dọpụta ọkpọkọ na nha dị iche iche, ihe niile ga-ejikọta ọnụ. Nke a ga-eme ka ọrụ ngwa ngwa na mfe.

Ihe eji eme enyi na enyi

Na Siemens hard ware na onye ọrụ enyi na enyi software nke ụlọ ọrụ anyị mere. Nweta ọrụ mmekọrịta yana extruder, mee ka ọrụ dị mfe yana ngwa ngwa. Ọzọkwa ndị ahịa nwere ike họrọ naanị ụfọdụ n'ime claws na-arụ ọrụ ịdọrọ ukwuu nta ọkpọkọ.

Nchekwa nrụgide ikuku dị iche

Ụkwụ ọ bụla nwere njikwa nrụgide ikuku nke ya, nke ziri ezi, ọrụ dị mfe.

. Akwa ịdọrọ ike na-enweghị ida ọdịdị nke ọkpọkọ

. Ejiri 2, 3, 4, 6, 8,10 ma ọ bụ 12 caterpillars dị ka ngwa ahụ siri dị.

. Servo moto ịnya ụgbọ ala maka inye torque kwụsiri ike na ịgba ọsọ

. Ndokwa moto nke caterpillars dị ala

. Ọrụ dị mfe

. Nchedo mechiri emechi kpamkpam maka nchekwa kacha

. Ndị na-ebugharị ụdọ nwere akwa rọba pụrụ iche na agbụ nke na-enweghị akara na ọkpọkọ.

. Mmekọrịta yana ọsọ ịghasa extruder na-enye ohere mmepụta kwụsiri ike n'oge mgbanwe ọsọ mmepụta

Igwe eji egbutu ọkpọkọ

Onye na-egbutu ọkpọkọ rọba nke a na-akpọkwa ọkpọkọ ọkpọkọ nke Siemens PLC na-achịkwa, na-arụkọ ọrụ ọnụ na-ebupụ unit iji nweta nkenke ịkpụ. Ndị ahịa nwere ike ịtọ ogologo ọkpọkọ ha chọrọ ịkpụ. Multi-fied-na omume maka mmezu nke otu ọnwụ usoro (chebe agụba na nkwọ, gbochie si agụba na nkwọ rapaara n'ihi na oké ọkpọkọ na bee ihu ọkpọkọ bụ ire ụtọ).

Ngwaọrụ Mkpuchi Eluigwe na Ala

Tinye ngwaọrụ clamping zuru ụwa ọnụ maka nha ọkpọkọ dị iche iche, ọ dịghị mkpa ịgbanwe ngwaọrụ clamping mgbe nha ọkpọkọ gbanwere.

Hụrụ na agụba na-agbanwe agbanwe

Ụfọdụ cutters na-onwem na ma saw na agụba. Ịhụ na ịcha agụba na-agbanwe agbanwe maka nha ọkpọkọ dị iche iche. Ọzọkwa, saw na agụba nwere ike na-arụkọ ọrụ ọnụ maka pụrụ iche chọrọ.

Ndozi Elu Central

Na ngwaọrụ ngbanwe ọkụ eletrik maka ngwaọrụ mpịachi. Na-arụ ọrụ ngwa ngwa na mfe. Na mgba ọkụ oke iji hụ na nchekwa.

. Mmekọrịta akpaaka na ọsọ extrusion

. Planetary kwadebere na diski na-egwe ọka cutter maka ịkpụ na chamfering

. Chip-free nke nwere agụba diski iji hụ na ịcha elu dị mma na-enweghị uzuzu ọ bụla

. Ogwe njikwa ihuenyo metụ aka

. A na-ebugharị mmegharị niile site na njikwa njikwa ma na-achịkwa ya

. Ikpochi ọkpọkọ site na iji njigide zuru ụwa ọnụ maka ịrụ ọrụ dị mfe

. Mkpa mmezi obere

. Igwe mechiri emechi yana echekwara maka oke nchekwa

Stacker

Iji kwado ma budata ọkpọkọ. Enwere ike ịhazi ogologo stacker.

Pipe elu nchedo

Na ala, iji kpuchido elu ọkpọkọ mgbe ọ na-akpụ akpụ.

Ndozi Elu Central

Na ngwaọrụ ngbanwe dị mfe iji dozie ịdị elu nke etiti maka nha ọkpọkọ dị iche iche.

Coiler

Iji kpoo ọkpọkọ n'ime rola, dị mfe maka nchekwa na njem. A na-ejikarị ọkpọkọ dị n'okpuru nha 110mm. Nwee otu ọdụ ọdụ na ọdụ abụọ maka nhọrọ.

Iji servo moto

Enwere ike ịhọrọ moto servo maka mbugharị ọkpọkọ na ikuku, nke ziri ezi na ngbanwe ọkpọkọ ka mma.

Data teknụzụ

| Oke dayameta (mm) | Ihe nlereanya extruder | Oke. Ike(kg/h) | Oke. ọsọ ahịrị (m/min) | Ike extruder (KW) |

| 20-63 | SJ65/33 | 220 | 12 | 55 |

| 20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Dual | SJ60/38 | 460 | 15×2 | 110 |

| 20-110 | SJ65/33 | 220 | 12 | 55 |

| 20-110 | SJ60/38 | 460 | 30 | 110 |

| 20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| 1000-1600 | SJ 90/38 SJ 90/38 | 1,900 | 0.6 | 280 280 |