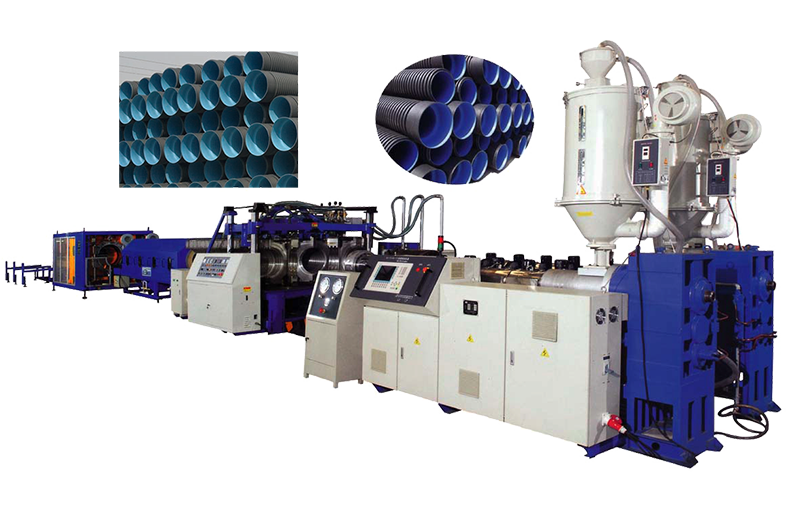

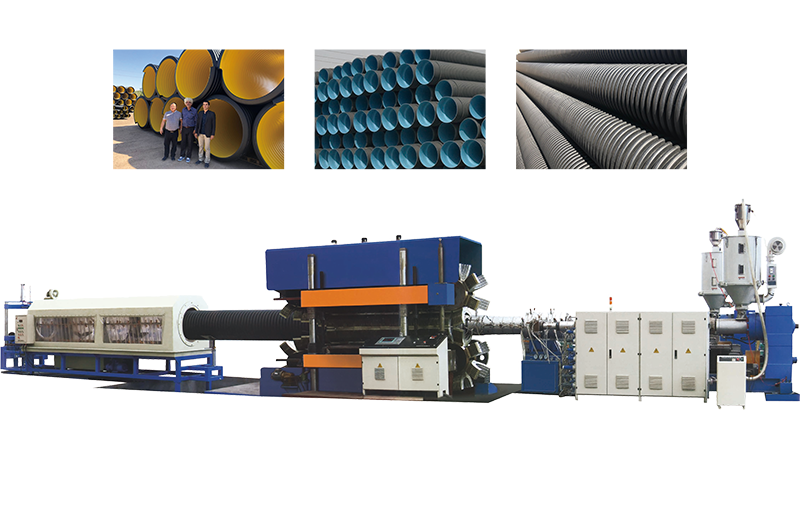

Ọsọ PE PP dị elu (PVC) eriri extrusion ọkpọkọ

Nkọwa

A na-eji igwe ọkpọkọ rọba na-emepụta ọkpọkọ rọba, bụ nke a na-ejikarị na drainage obodo, usoro nsị mmiri, ọrụ okporo ụzọ, ọrụ nchekwa mmiri nke ala ubi, ma nwee ike iji ya rụọ ọrụ njem ụgbọ mmiri mmiri na-egwupụta mmiri, nke nwere ọtụtụ ngwa ngwa. Corrugated ọkpọkọ na-eme igwe nwere uru nke elu mmepụta, kwụsiri ike extrusion na elu ogo nke akpaaka. Enwere ike ịmepụta extruder dịka ọnọdụ pụrụ iche nke ihe onye ọrụ, dị ka PE PP ma ọ bụ PVC. PE PP okpukpu abụọ na-arụ ọrụ ọkpọkọ na-eji ụdị ọhụụ dị elu nke otu/ejima ịghasa extruder dị elu. Igwe ọkpọkọ PVC corrugated na-eji nnukwu ejima dị larịị ma ọ bụ conical ejima extruder. Na otu oyi akwa na akwa abụọ maka nhọrọ. Iji mee ọkpọkọ corrugated mgbidi abụọ, e nwere ụdị abụọ;kehoraizin abụọ mgbidi corrugated anwụrụ extrusion ahịrịnavetikal mgbidi okpukpu abụọ corrugated ọkpọkọ extrusion ahịrị.

Usoro Usoro

Akụrụngwa → Ngwakọta → Vacuum Feeder → Plastic Hopper Drier → Extruder → Extrusion Mold → Akpụkpọ anụ → Igwe na-eme ka mmiri dị jụụ → Ịgbasa mmiri na-ekpo ọkụ → igwe na-egbutu → Stacker

Atụmatụ na Uru

1. HDPE adopts ọhụrụ ụdị elu-arụmọrụ otu / ejima ịghasa extruder, na PVC adopts a nnukwu flat ejima ma ọ bụ conical ejima extruder. Nnukwu conical ejima-ịghasa extruder ma ọ bụ yiri ejima-ịghasa extruder nwere ike na-aghọta magburu onwe plasticization na ala okpomọkụ na ike extrusion.

2. Usoro nju oyi nke modul na-amanye mmiri jụrụ oyi, nke na-eme ka ọsọ dị jụụ nke modul dịkwuo mma, ka o wee nweta mmepụta ngwa ngwa.

3. The corrugated ọkpọkọ eriri na-akpọ abụọ mgbidi corrugated ọkpọkọ igwe akara nwere ike na-aghọta na-line flaring iji hụ na dị iche iche Njirimara nke kpụrụ ọkpọkọ izute ụkpụrụ.

4. valvụ na-emezi ihe na-ebubata na-eme ka nrụgide guzosie ike ma bụrụ nke a pụrụ ịdabere na ya.

5. Ụdị corrugator kwụ ọtọ

6. Plateform na-arụ ọrụ na-agbanwe n'ụzọ atọ.

7. Usoro nchebe akpaaka na-amalite ma rụọ ọrụ na-alọghachi mgbe ọkụ kwụsịrị.

8. Ụlọ ọrụ mmanye akpaaka

9. A na-eji ihe mkpuchi aluminom pụrụ iche na-emepụta ihe na-emepụta ihe na-emepụta ihe dị arọ, ike dị elu, ezigbo ihe na-eguzogide ọgwụ, obere co-arụ ọrụ nke ọma nke mgbasawanye ọkụ.

10. Ikuku jụrụ na mmiri jụrụ nke ọma jụrụ corrugated ebu na-akpụ ọkpọkọ ngwa ngwa.

11. Igwe na-egbutu ọkpọkọ nke corrugated nwere uru nke oke nkenke na enweghị ájá.

12. The zuru akara adopts PLC micro-kọmputa akara usoro nke nwere ike anya na-egosi gbazee okpomọkụ na nrụgide, akpụ ọsọ, njehie mkpu na nwekwara ike nchekwa ikike nke isi usoro.

Nkọwa

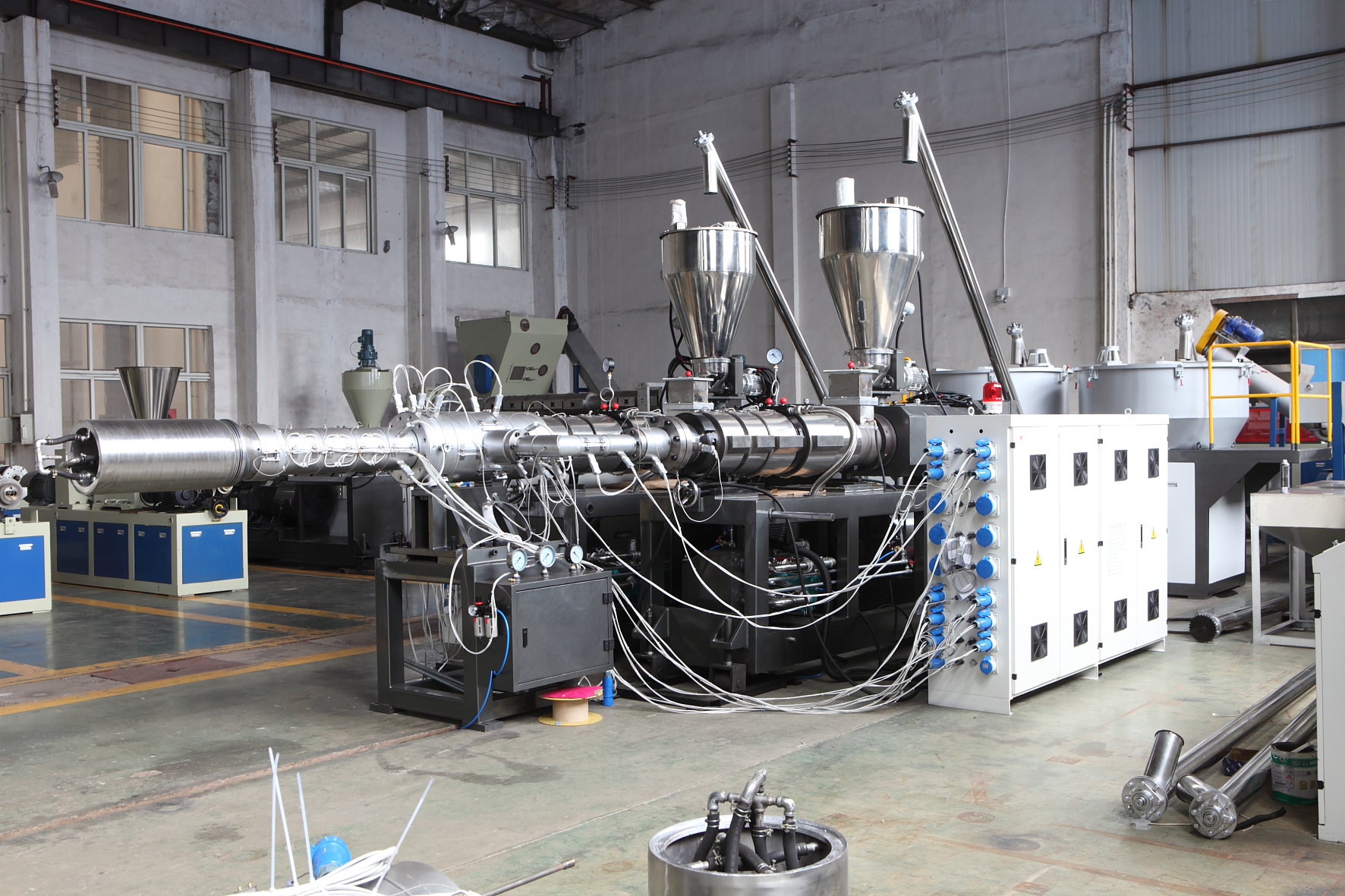

Otu ịghasa Extruder maka PE/PP

Dabere na 33: 1 L / D ruru maka ịghasa imewe, anyị emepụtala 38: 1 L / D ruru. E jiri ya tụnyere 33: 1 ratio, 38: 1 ratio nwere uru nke 100% plasticization, na-abawanye mmepụta ikike site 30%, belata ike oriri ruo 30% na iru fọrọ nke nta linear extrusion arụmọrụ. Nabata nha L/D 38:1 maka ihe na-amaghị nwoke na L/D 33:1 ịghasa maka ihe ejigharịgharị.

Simens Touch Screen na PLC

Tinye mmemme nke ụlọ ọrụ anyị mepụtara, nwee Bekee ma ọ bụ asụsụ ndị ọzọ ka ọ bụrụ ntinye n'ime usoro ahụ.

Ihe owuwu gburugburu Barrel

Nri akụkụ gbọmgbọm na-eji usoro okirikiri, iji hụ na nri akụrụngwa kwụsiri ike ma na-abawanye ikike inye nri.

Pụrụ iche imewe nke ịghasa

Emebere ịghasa na ihe owuwu pụrụ iche, iji hụ na ọ dị mma plasticization na ịgwakọta. Ihe agbazeghị agbaze enweghị ike ịgafe akụkụ nke ịghasa.

Igwe ọkụ seramiiki jụrụ ikuku

Igwe na-ekpo ọkụ seramiiki na-eme ka ọ dị ogologo ndụ ọrụ. Nhazi a bụ ịbawanye mpaghara nke ikpo ọkụ na-akpọtụrụ ikuku. Ka inwe mmetụta dị jụụ ikuku ka mma.

Igbe igbe dị mma

A ga-ahụta izi ezi Gear 5-6 ọkwa yana obere mkpọtụ n'okpuru 75dB. Kọmpat Ọdịdị ma na elu torque.

Conical Twin Screw Extruder maka PVC

Ma conical ejima ịghasa extruder na yiri ejima ịghasa extruder nwere ike itinye na-emepụta PVC. Site na teknụzụ kachasị ọhụrụ, iji wedata ike ma hụ na ikike. Dị ka usoro dị iche iche si dị, anyị na-enye nhazi ihe nkedo dị iche iche iji hụ na mmetụta plasticizing dị mma na ikike dị elu.

Akpụkpọ anụ

Ma elu oyi akwa na ime oyi akwa na-extruded n'ime anwụ isi. A na-etinye ọwa ọ bụla ihe na-eruba n'ime isi anwụ. Ọwa ọ bụla na-esote ọgwụgwọ okpomọkụ na polishing mirror iji hụ na ihe na-aga nke ọma. Ọzọkwa anwụ isi na-enye abịakọrọ ikuku n'etiti ma oyi akwa. A na-eji aka aka calibration mee ka oyi akwa dị n'ime dị jụụ ka ọ bụrụ ọkpọkọ dị larịị ma dịkwa larịị n'ime. Mmiri nrụgide na-asọba n'ime aka aka nhazi ka ọ nwee mmetụta dị jụụ. A na-emepụta Vacuum n'elu elu aka aka mgbe ọ na-emepụta nnukwu ọkpọkọ dayameta, hụ na ọ dị okirikiri.

Ịkpụ ebu

CNC machining na-eme ka akụkụ ziri ezi. Ọwa ikuku na-ekpo ọkụ na ọwa mmiri na-eme ka mmiri dị jụụ nke nwere nnukwu akụkụ obe na-eme ka ọ kwụsie ike, dị elu, na ịrụ ọrụ nke ọma. Ihe modul bụ ihe dị elu nke aluminom alloy, na-enwe mmetụta dị elu nke thermal conductivity, elu siri ike, na akwa mkpuchi mkpuchi. Nhazi modul na-anakwere usoro nkedo nrụgide dị mkpa, nwere udidi siri ike yana nkwụsi ike dị elu. Ngwọta dị n'ime ime nke modul na-eme ka ike na ike nke modul ahụ dịkwuo mma, nke na-enye aka na nhazi zuru oke nke ripples. The ebu adopts CNC machining iji hụ na ya izi ezi na ezigbo ọrụ.

Mmiri jụrụ oyi akpụ igwe

A na-eji igwe na-eme ka mmiri dị jụụ na-edobe ma na-ebugharị corrugated ebu, a na-emepụta oghere iji banye n'elu oyi akwa n'ime corrugated ebu iji mepụta udi corrugate. Site n'ịkwagharị corrugated ebu, a na-ewepụkwa ọkpọkọ na corrugator.

Sistemụ mmanye mmanye akpaaka

Na-akpa mmanu ngwo ahụ iji mee ka corrugated ebu na-aga nke ọma.

Nbufe Gear Rack

A na-edobe ihe mkpuchi gia n'elu ihe akpụ akpụ. All gia racks bụ mgbe nitriding na kpo oku ọgwụgwọ, ogologo ogologo eyi iguzogide.

Sistemụ mmezi nke elu

Jiri eletrọnịkị dozie etiti elu maka nha corrugated dị iche iche. Na ogidi anọ, hụ na ngbanwe kwụsiri ike na nke ziri ezi.

Sistemụ na-emezigharị ụjọ

Ka ịgbanwee ike nke ebu na-akpụ akpụ, mee ka ebu na-aga nke ọma.

Valve dị nhata

Iji chịkwaa ikuku kwụsiri ike na nke ziri ezi, iji mepụta ezigbo ọkpọkọ na ụdị oghere.

Sistemụ jụrụ oyi

Na ma mmiri jụrụ oyi na ikuku jụrụ usoro, ka mma mma mmetụta, ezi na ngwa ngwa ọkpọkọ akpụ.

UPS ike ndabere

Mgbe ike dara, ike nkwado UPS ga-enye ike na corrugator iji wepụ ọkpọkọ na aka aka calibration. Ka ịzenarị ọkpọkọ rapaara n'aka aka nke nrụzi mgbe ọkpọkọ jụrụ oyi na mbelata.

fesa tank mmiri jụrụ oyi

A na-eji tankị jụrụ oyi mee ka ọkpọkọ dị jụụ.

Ntugharị inyeaka

Site na mbupu ihe inyeaka, ngwaọrụ traction na-agbanwekwa. Iji dọpụ ọkpọkọ n'ihu.

Ọdịmma fesa nozzle

Ọdịmma ịgba nozzles nwere mmetụta dị jụụ ka mma yana adịghị mfe egbochi ya site na adịghị ọcha.

Ihe nzacha mmiri mmiri

Na nzacha n'ime tank mmiri, iji zere nnukwu adịghị ọcha mgbe mmiri dị n'èzí batara.

Igwe eji egbutu ọkpọkọ

Igwe na-egbutu ọkpọkọ corrugated dị elu na enweghị ájá.

Ngwaọrụ mwepu aluminum

Tinye ngwaọrụ mpịachi aluminom maka nha ọkpọkọ dị iche iche. Nke ọ bụla size na ya onwe clamping ngwaọrụ, ọ dịghị mkpa ịgbanwe Central Central elu mgbe dị iche iche ọkpọkọ nha.

Sistemụ mmekọrịta

Mgbo na inverter na-eji ebe a na-egbutu ihe. N'oge a na-egbutu osisi, ebe a na-egbutu ya na corrugator na-aga n'otu oge iji zere nrụrụ ọkpọkọ.

Ịcha mma okpukpu abụọ

Iji mma abụọ na-egbukọ ọnụ, iji hụ na ebipụla akụkụ njedebe nke oghere.

Stacker

Iji kwado ma budata ọkpọkọ. Enwere ike ịhazi ogologo stacker.

Iji kwado ma budata ọkpọkọ. Enwere ike ịhazi ogologo stacker.

Iji bugharịa ọkpọkọ corrugated were were na stacker, anyị na-etinye igwe anaghị agba nchara n'elu stacker.

Iji kpoo ọkpọkọ n'ime rola, dị mfe maka nchekwa na njem. A na-ejikarị ọkpọkọ dị n'okpuru nha 110mm. Nwee otu ọdụ ọdụ na ọdụ abụọ maka nhọrọ.

Data teknụzụ

| Nlereanya | Nha ọkpọkọ (mm) | Onye na-apụ apụ | Nsonaazụ (kg/h) | Ọsọ (m/min) | Ngụkọta ike(KW) | Akpụkpọ (ụzọ abụọ) | Usoro jụrụ oyi |

| SGB250 | 90-250 | SJ65 SJ75 | 300 | 1-4 | 150 | 48 | Ikuku jụrụ oyi na mmiri jụrụ oyi |

| SGB500 | 200-500 | SJ75 SJ90 | 600 | 1-4 | 200 | 40 | Ikuku jụrụ oyi na mmiri jụrụ oyi |